Multi-body simulation (MBS) laboratory

The Laboratory and Competence Centre for Multibody Simulation sees itself as a partner and service provider for companies and students in the fields of multibody dynamics, driving simulation and transmission technology.

News

Funding in the field of digital twins

The Multibody Simulation Laboratory is receiving €500,000 from the Walter and Elfriede Niehoff Foundation for research in the field of digital twins for small and medium-sized enterprises in the mechanical engineering sector.

What does the laboratory do?

For the topics of multi-body dynamics, driving simulation and transmission technology, the laboratory has access to a wide range of software and powerful hardware. A broad spectrum of experts from OTH Regensburg, and in particular from the Faculty of Mechanical Engineering, is available to address issues from these various disciplines.

Thanks to the diverse range of projects already completed, close contact with various software manufacturers and cooperation with other laboratories, the laboratory is unique in the field of multi-body simulation.

Multi-body simulation (MBS) is a method of numerical simulation in which real technical systems with moving components are replicated using virtual prototypes, known as ‘digital twins’. With the help of these virtual prototypes, the behaviour of a product or machine can be predicted in advance solely through simulations, without the need for costly and sometimes lengthy tests with expensive real prototypes. In product development, these predictions meet the desire for shorter development times while reducing costs and improving quality. For this reason, multi-body simulation is often used early in the product development process, primarily in pre-series and series development. In most cases, MKS programmes are used for this purpose. Based on the virtual models, these programmes create the corresponding equations of motion, perform simulation calculations and display the results in animated form or as diagrams. The results also allow the movement behaviour of the components to be examined. At the same time, they can be used to determine the loads on the components, which are essential for their optimal design. In addition, MKS programmes play an important role in fault analysis, enabling existing and difficult-to-trace problems to be investigated virtually.

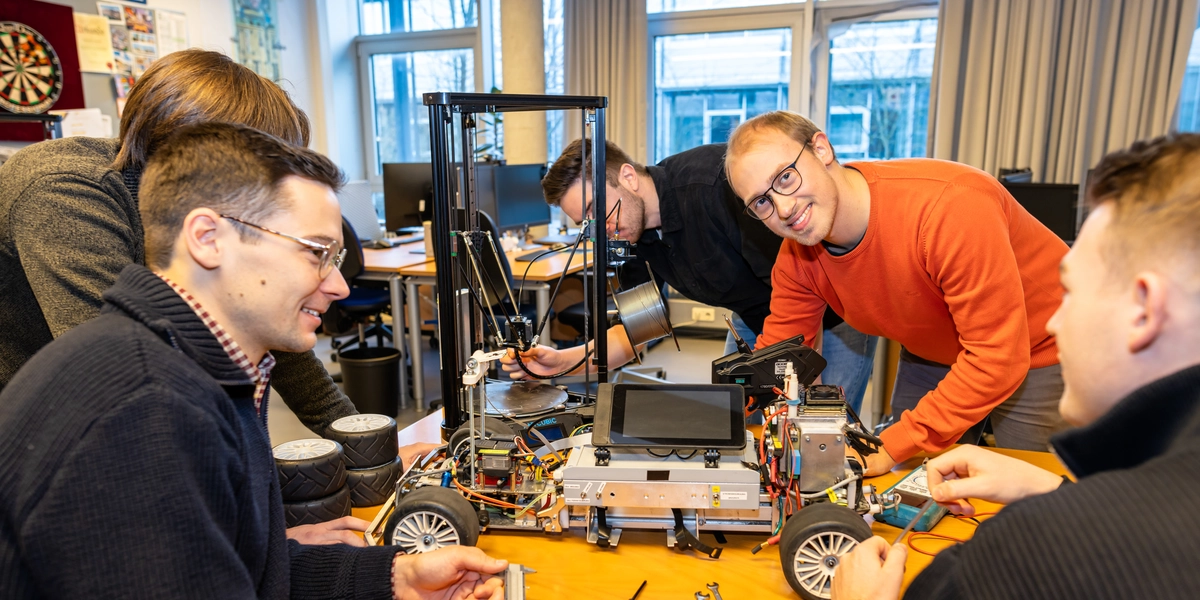

Various topics and projects are being worked on. In addition to student projects, research and development projects are also being carried out with several companies in eastern Bavaria and beyond. The spectrum ranges from classic pre-development work and specific research questions to software benchmarks.

Key topics in the MKS laboratory:

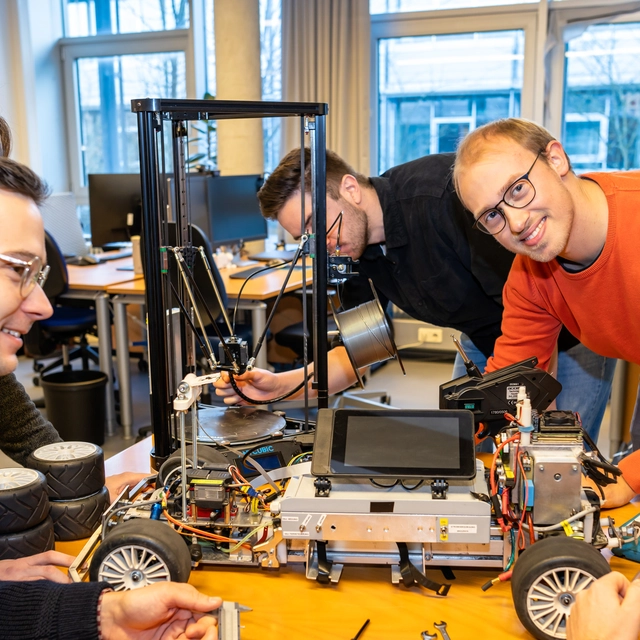

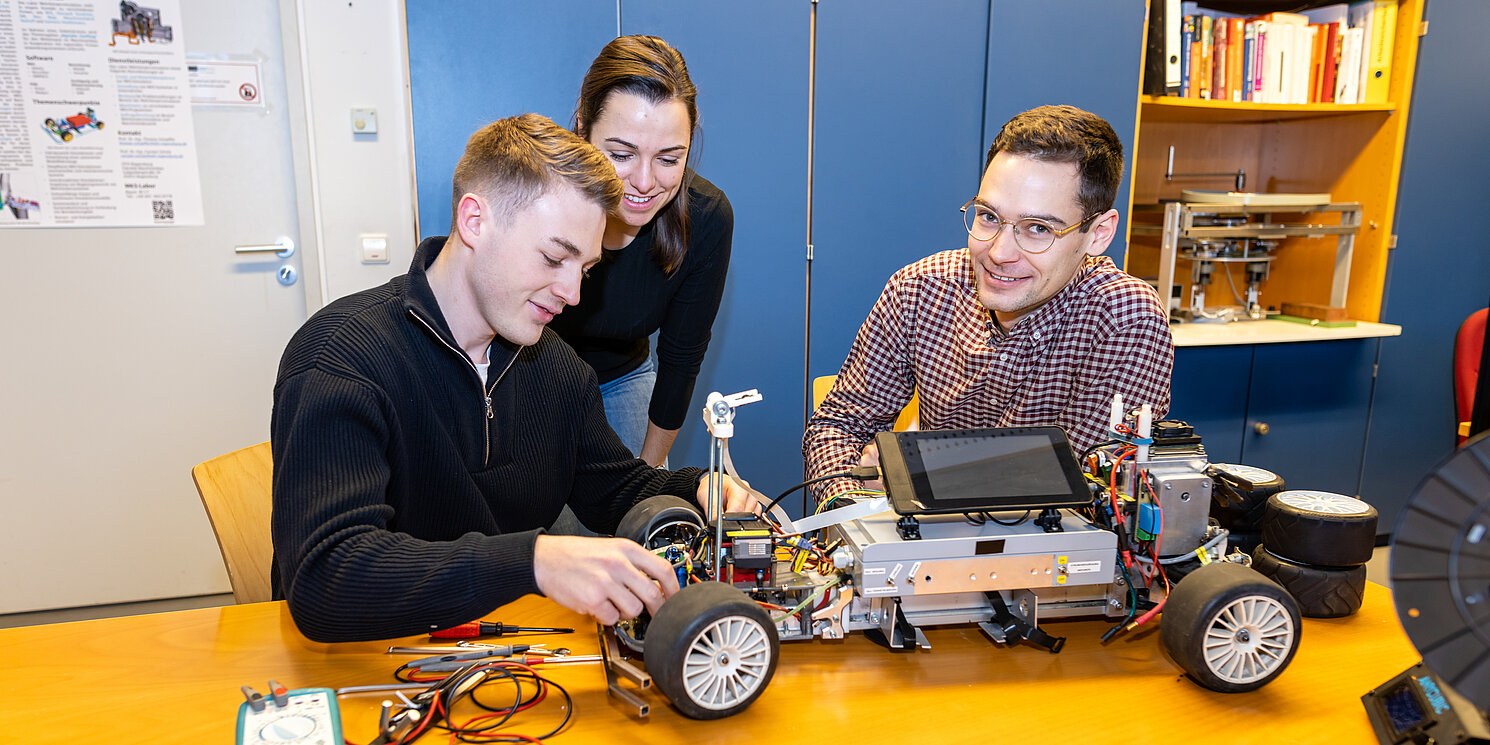

- Driving dynamics simulations and development of an autonomous model vehicle

- Detailed MKS simulations of mechanical and mechatronic systems

- Interdisciplinary simulations: coupling of control engineering with multi-body systems

- Real-time capable linear and non-linear simulation models

- System analysis and system tuning in connection with operational stability

- Belt and energy chain simulation

Working group ‘Digital twin for SMEs in mechanical engineering’

As part of a working group based at the Multibody Simulation Laboratory, the topic of ‘digital twins’ for small and medium-sized enterprises in the mechanical engineering sector is being researched in cooperation with regional companies.

The aim is to make the use of digital twins in the field of multibody dynamics efficient and profitable for small and medium-sized enterprises.

In addition to the Multibody Simulation Laboratory, the following companies are currently participating in the working group:

- BHS Corrugated Maschinen- und Anlagenbau GmbH

- GE Wind Energy

- Maschinenfabrik Reinhausen

- Max Bögl

- Maschinenfabrik Niehoff

- Siemens Healthineers

Publications

- Schulz, C., Vogl, Y., et al. Vor- und Nachteile einer Lumped-Mass-Modellierung von Förderbändern am Beispiel eines Zwei-Walzensystems (2024). https://link.springer.com/article/10.1007/s10010-024-00736-4

(Advantages and disadvantages of lumped mass modelling of conveyor belts using the example of a two-roller system) - Schulz, C., Vogl, Y., et al. Lumped-Mass-Modellierung von Förderbändern am Beispiel eines Zwei-Walzensystems (Dresdner Maschinenelemente Kolloquium 2024).

(Lumped mass modelling of conveyor belts using the example of a two-roller system) - Schuderer, M., Rill, G., Schaeffer, T. et al. Friction modeling from a practical point of view. Multibody Syst Dyn (2024). https://doi.org/10.1007/s11044-024-09978-0

- Rill, G.; Schuderer, M. A Second-Order Dynamic Friction Model Compared to Commercial Stick–Slip Models. Modelling 2023, 4, 366-381. https://doi.org/10.3390/modelling4030021

- Rill, G., Schaeffer, T. & Schuderer, M. LuGre or not LuGre. Multibody Syst Dyn (2023). https://doi.org/10.1007/s11044-023-09909-5